Solution

We provide the customize solution according to your technology and process requirements!

+8618538579801

The plantain flour processing machine includes plantain peeling machine, plantain banana slicer, plantain banana slice dryer, plantain banana milling machine. Banana powder is milky yellow loose particles with the sweet and sweet taste of banana pulp. It maintains the color, flavor and main nutrients of banana pulp. It does not contain artificial additives and auxiliary materials such as starch, dextrin and sugar. It is a banana made of pure powder.

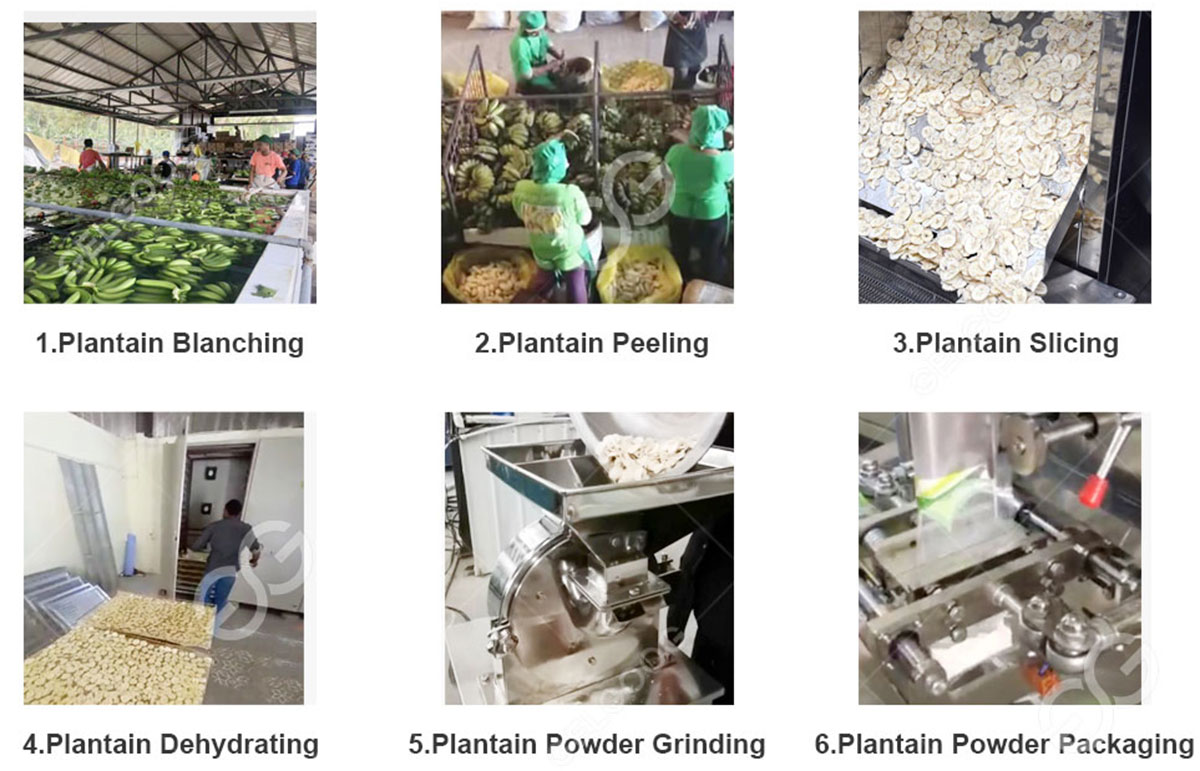

Process flow of banana powder production line:Raw materials/plantain—transportation—multi-level cleaning—blanching—cooling—peeling—slicing—lifting—color protection—water removal—drying—crushing—milling—packing

In order to produce high-quality plantain powder, fresh plantain roots are harvested 10-12 months after planting. Fresh roots must be healthy, free of rot, and handled properly on the farm. The roots should be processed within 24 hours after harvest.

1. Plantain peeling machine

The first step in the processing line of the plantain flour mill is to peel the plantain. The green banana peeler adopts manual feeding and automatic peeling process, which can quickly remove the green banana peel, peeling clean and not damaged. In addition, the peeling machine is suitable for any size, and the arc is separated from the plantain. The peeling effect is perfect. It is unique in the current global banana peeling machine and is the best product for banana plants in the world.

2. Banana slicing machine

The automatic banana slice cutting machine is used to cut bananas into slices. The cutting surface is smooth and uniform, the thickness is adjustable, and it is not crushed. The banana slice cutting machine is made of food grade stainless steel SUS304, which is healthy and safe. Simple operation and high efficiency.

3. Banana multilayer dryer

Regarding plantain drying, we can use an industrial plantain dryer to dry in an oven or other dryers for a short time. Fully automatic multi-layer banana chip dryer, also used for dehydration of vegetables, medicines and fruits. Bananas are white or light yellow after drying and can be processed into large banana powder. Different types of drying equipment space can meet the production of different materials.

3. Banana powder grinding machine

After the plantain is dried, it is time to grind the dried plantain slices to obtain plantain powder. The water-cooled stainless steel banana mill adopts high-quality stainless steel materials and has a turbine crushing design. Suitable for grinding and processing of banana powder, onion powder, garlic powder, pepper powder and medicinal powder, the fineness can reach 10~120 mesh

Water cooling system

The water cooling device is used to reduce the temperature of the grinding chamber. In the grinding process, if there is no water cooling system, the temperature of the grinding chamber will reach 70-80 degrees Celsius. Understand such high temperature; it will damage spices or herbs (chemical composition and smell may be affected by temperature). Temperature will also reduce the grinding speed.

4. Banana powder rotary vibrating sieve

Due to the unique structure and working principle, the rotary vibrating screen is especially suitable for the classification of small particles and fine powder materials. The screen surface and screen frame of the rotary vibrating screen can be manufactured by using a variety of materials and different processes, and can be conveniently used in multiple layers. The rotary vibrating screen is a fully enclosed structure, basically no material dust spills and pollution, and can be easily added with auxiliary facilities such as drying, cooling, dust removal, and cleaning.

5. Small bag banana flour packaging machine

The automatic small bag banana powder packaging machine is used to pack banana powder in small bags, such as 10g, 20g, 50g, 100g. With spiral feeding design, it is suitable for banana powder, onion powder, ginger powder, chili powder, coffee powder, flour, bean powder, desiccant, medicine and other different powders. This sachet bag packaging machine can automatically complete pillow bag forming, Filling, sealing, cutting, date printing and other processes.

1. The professional design of plantain overcomes the characteristics of plantain's high fiber content and heavy pectin.

2. Optimize the process, continuous and smooth, simple and efficient

3. White pure flour, good quality

4. The whole machine runs stably with low failure rate

5. Low energy consumption, fewer people, and low processing cost

6. The complete set of equipment is easy to operate and easy to maintain

Banana Chips

Banana chips contain a lot of protein and minerals. Regular consumption can maintain the balance of sodium and potassium in the body, diuresis, reduce swelling, and regulate blood pressure. Supplement energy: Banana chips are rich in sugars, which can provide energy to the human body after consumption. Weight loss: Banana slices contain a lot of dietary fiber, which is easy to produce satiety after eating, can promote gastrointestinal peristalsis and promote metabolism.

Banana powder

Banana powder can be used as a raw material or additive in the food industry for beverages, dairy products, instant noodles, sweets, etc. Congee seasoning, flushing juice, fruit mask, making cakes and breads, moon cake fillings, children's nutritional supplements, sick liquid food, making ice cream, jelly pudding, health care products, etc.

Share This Post,Choose Your Platform!